CASE STUDIES

Why BAS KOREA?

CASE STUDIES

Ship Spare Part Optimization Service Case

A case study showcasing BAS KOREA’s expertise in delivering optimized ship spare part services tailored to customer needs

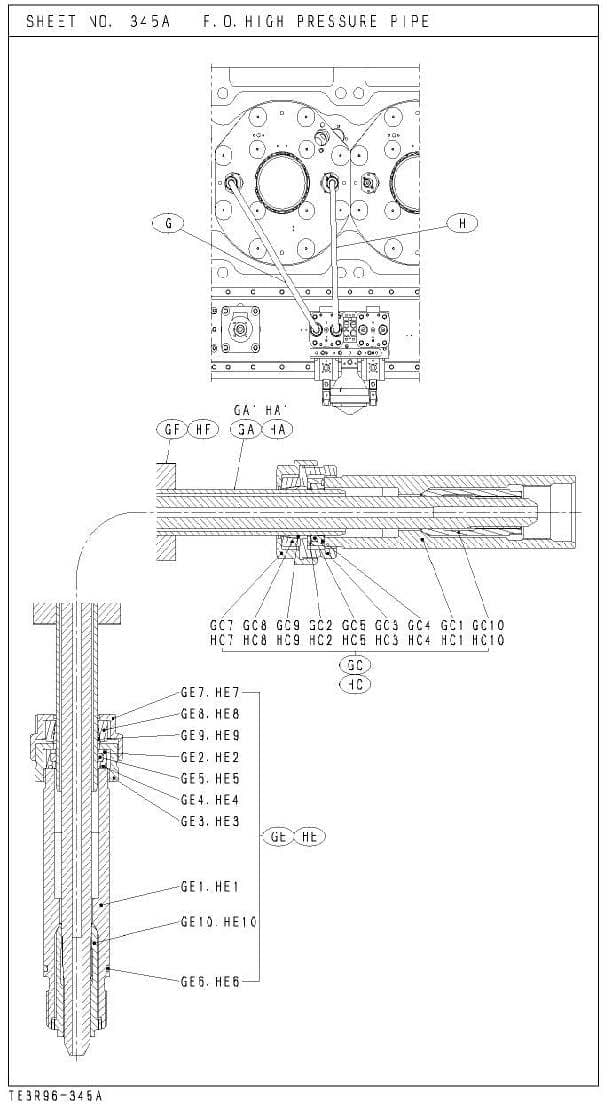

F.O. High-Pressure Pipe Assembly Quotation Inquiry

Customer sends a quotation inquiry for F.O. high-pressure pipe assembly.

Measurement Method Image Delivery

BAS KOREA delivers an image containing measurement methods to the customer for specification confirmation.

Direct Measurement on Vessel and Image Transmission

Customer measures directly on the vessel and sends the image to BAS KOREA.

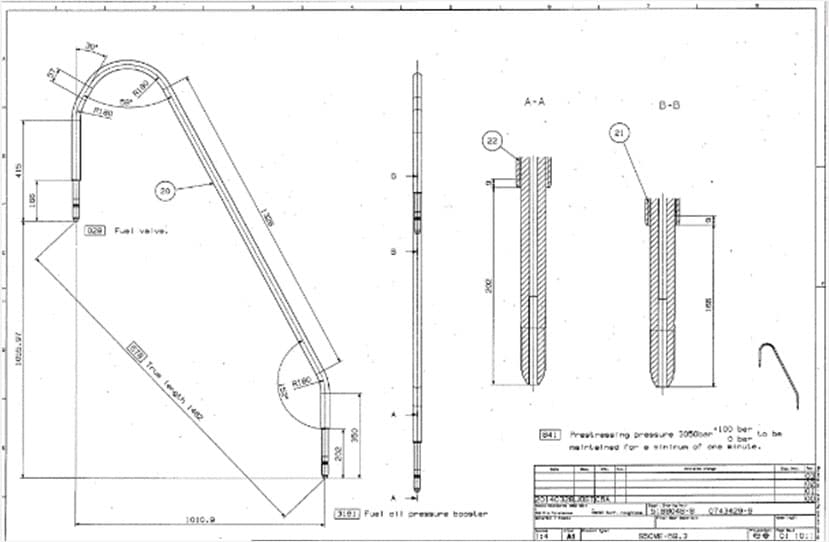

Blueprint (Drawing) Delivery

BAS KOREA confirms the specifications and delivers a blueprint (drawing) to help the customer understand.

Logistics Service Case

Multi-country parts integration shipping project

Customer Requirements & Background

The customer placed an order in early December 2024, planning to complete departure by early January 2025. Subsequently, the customer requested sequential delivery of ship parts supplied from multiple countries, requiring delivery to a designated vessel docked at Pyeongtaek Port.

Order Placed for BAS KOREA Products

The client placed an order for Korean-made spare parts supplied by BAS KOREA to be delivered to the vessel.

Shipment Readiness Reported

BAS KOREA reported that all ordered Korean parts were ready for shipment.

[Delivery Agency] Request for Japanese Parts

The client inquired about customs clearance and delivery agency for air-shipped parts from Japan (Non-BAS KOREA products).

[Delivery Agency] Request for Taiwanese Parts

An additional request was made for the delivery agency of air-shipped parts from Taiwan (Non-BAS KOREA products).

Taiwanese Parts Arrival

The Taiwanese parts arrived at BAS KOREA's Busan warehouse for integrated management.

Japanese Parts Arrival

The Japanese parts arrived at the bonded warehouse in Pyeongtaek Port.

Cargo Consolidation & [Delivery Agency] China Request

Cargo from the Busan warehouse arrived at Pyeongtaek Port, and a new request was made for the delivery of parts from Mainland China (Non-BAS KOREA products).

Final Loading & Completion

All goods, including BAS KOREA products and third-party parts from Japan, Taiwan, and China, were successfully loaded onto the vessel.

Service Advantages

Logistics Service Optimization

Providing optimal scheduling plans to customers to reduce costs and ensure smooth follow-up deliveries

Real-time Monitoring

Real-time monitoring of regional delivery progress and vessel arrival/departure status to provide rapid updates

Risk Minimization

Minimizing potential risks and maximizing overall logistics efficiency